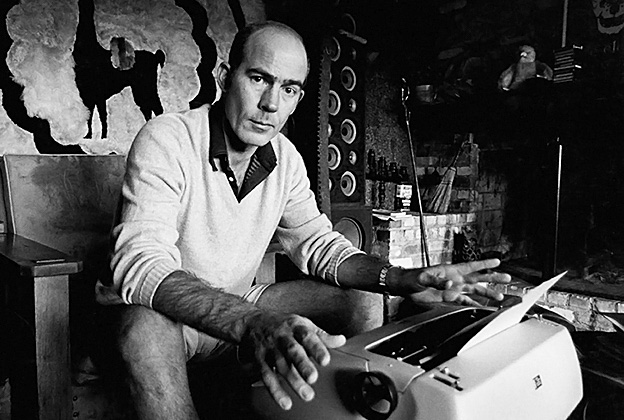

The TV business is uglier than most things. It is normally perceived as some kind of cruel and shallow money trench … a long plastic hallway where thieves and pimps run free and good men die like dogs…

– Hunter S. Thompson

I’ve had a couple extremely busy and rather annoying weeks at work. This past week, I altered somewhere close to twenty-five suits. That’s twenty-five suits while also doing a ridiculous number of fittings and a whole slew of other alterations as well. None of that is necessarily annoying on its own. What is annoying is when people aren’t good at scheduling and neglect to take into account the time it’ll take to complete an alteration.

As a TV and film tailor, I’m often the one who has a particular garment last, right before it goes off to set for an actor to wear. Which means, if someone didn’t schedule a fitting early enough or if they showed up late to a fitting, or they forgot about a fitting altogether, I’m the one who is under the gun. And I’m also the one who’ll get blamed if the clothes aren’t ready on time. Seems rather silly but that’s the way things normally work (no one ever said the film and TV business was a pretty or fair place).

As Hunter S. Thompson said, “The TV business is uglier than most things. It is normally perceived as some kind of cruel and shallow money trench through the heart of the journalism industry, a long plastic hallway where thieves and pimps run free and good men die like dogs, for no good reason.”

Often when I tell people that I work on television shows and movies, they say something like, “Oh that must be so much fun!” I suppose it has its moments but after the couple weeks I’ve just had, none of those moments seem all that fun.

So what can be done when you find yourself in work situations that are less than ideal? Here’s a short list of the things I do, or at least try to do when things are chaotic and disorganized around me.

Ask lots and lots of questions

If I’m in a fitting and I know the actor is scheduled to work the next day and the designers are putting multiple outfits on him, I ask things like, “So, this is what he’s wearing tomorrow?” or “For the courtroom scene, he should wear this?”

The only way you’ll be able to ask lots of questions, is if you read all the paperwork. Which leads to the next thing on the list (which perhaps should be the first thing…)

Read all the scheduling paperwork production puts out

For every episode, the assistant directors put out a schedule called a One Liner. A One Liner is organized by shoot day, starting with shoot day one. It lists every scene to be shot that day, and which actors are in that scene. Every actor in a show is assigned a cast number and that’s how they’re listed on the One Liner. At the end (or beginning) of the One liner, all the characters are listed in numerical order so you don’t have to know off the top of your head what number each actor is. It’s called a One Liner because the scene descriptions are traditionally one line.

You probably already know this but, tv shows and movies are not shot in the order of what you see as the final product. Also, remember that sometimes things change at the last minute. Double check everything. Read the daily call sheet. Check in with the Wardrobe Supervisor to make sure they have everything they need for the next day.

Some TV and film tailors rely on the Wardrobe Supervisor or Costume Designer to let them know what garments to complete when. I like to be a lot more proactive than that, mainly because I hate last minute, “Oh I forgot I needed this tomorrow. Can you alter this before you leave?”

These types of requests at the end of a ten hour day can often be avoided if you’re informed about the schedule and who works the next day and ask questions early on. People get tired and overwhelmed and forget things (I do sometimes, too!) but one thing I dislike a lot is when someone else’s forgetfulness or disorganization means I have to stay at work late. Because, believe me, most Costume Designers, after dropping a big late afternoon alteration in your lap, aren’t going to hang around at work with you while complete it.

So, I just try and stay super organized and prevent those types of situations. Also…

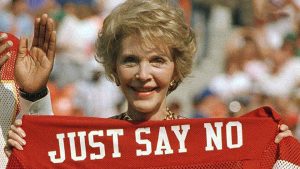

Know when to say no

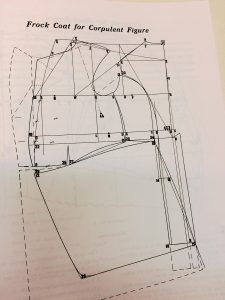

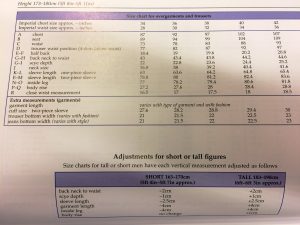

This is always difficult for me (and likely for most people) but, if a designer puts, say, a suit jacket on an actor that doesn’t fit him in the shoulders (and it’s a contemporary suit they just purchased in a store), the answer to, “Can you move the sleeves?” is, “I can but it’ll look a lot better if you buy a suit in the proper size. And we really don’t have time for that extensive of an alteration.”

Same goes for men’s shirts that don’t fit correctly in the neck. Buy a shirt in the proper neck size.

There are a lot of things I like about the film and television business but, one of the things I don’t, is the delusion that making TV shows is akin to something as important as curing cancer or launching rocket ships. TV is great and all but, it’s not world and peril stuff.